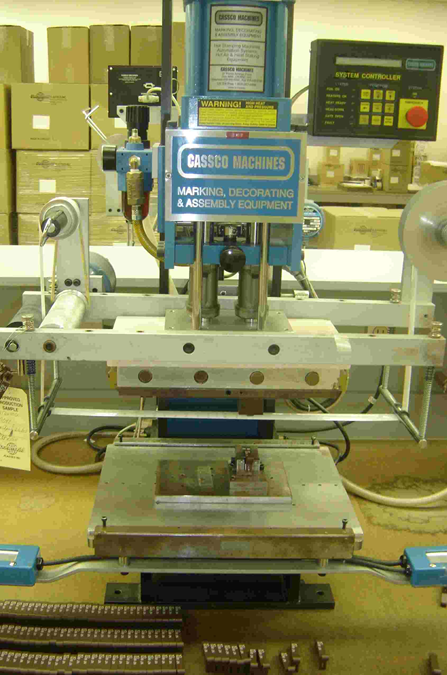

Application of pre-dried ink or foils to imprint your logo or other images on your part surface. Hot stamping is an environmentally-friendly method for creating images and designs on moulded parts.

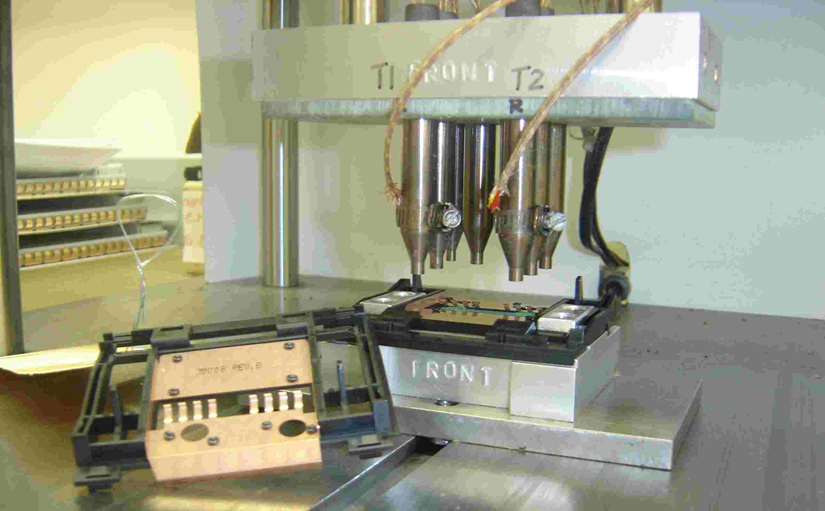

Indirect printing using special inks to imprint your logo or other images on your plastic part. Flexible pad allows the image to be printed on both flat and irregular surfaces.

Assembly methods to connect multiple moulded components without the use of consumable fasteners.

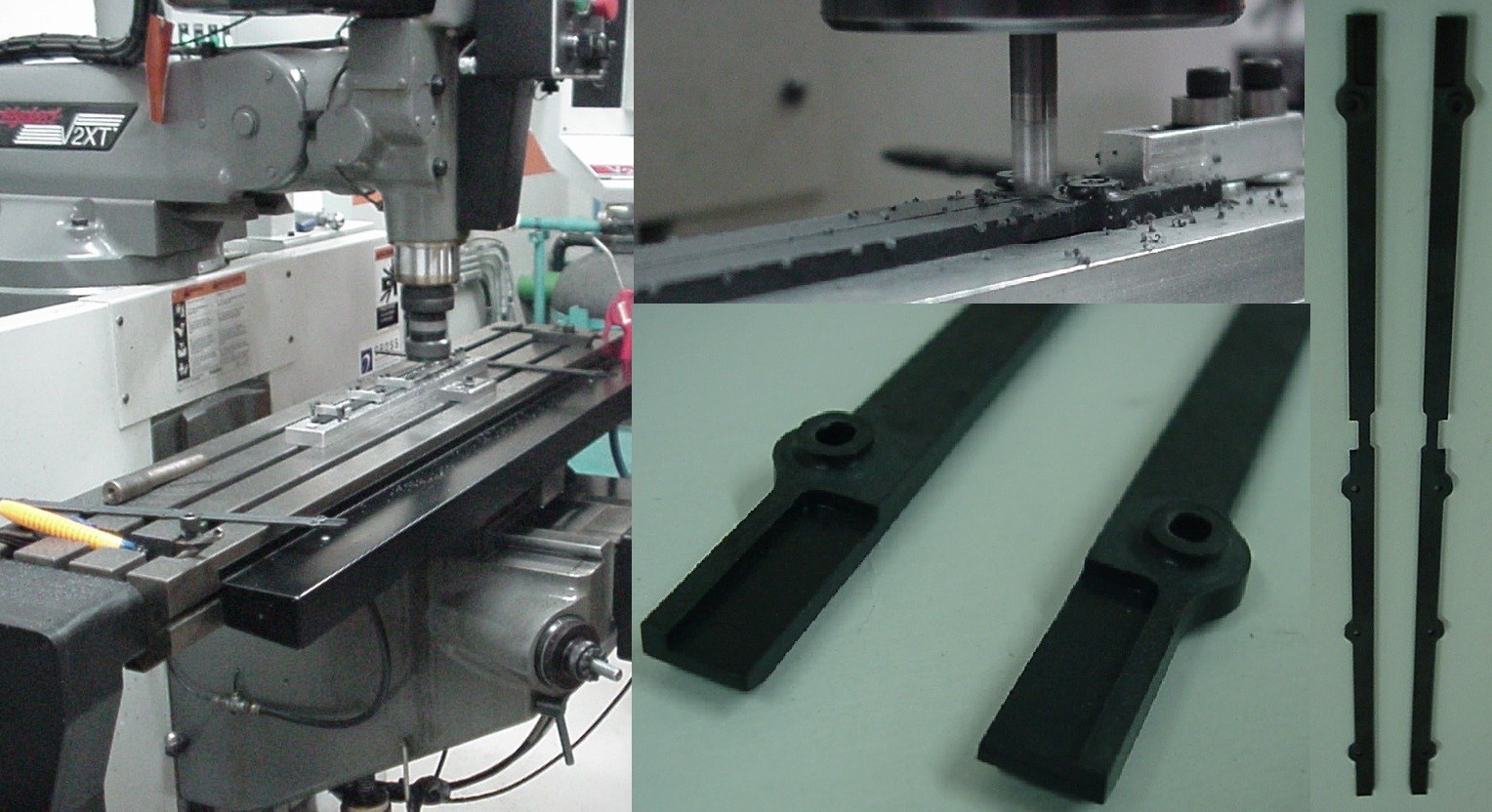

Injection-moulded parts are rarely in need of machining; however, this service is available for prototyping and modifying existing parts when you require it for your design.

Our assembly services range from manufacturing pieces that simply snap together to performing complex assemblies involving several plastic pieces, sealants, adhesives, metal inserts, plates, springs, screws and/or rivets.

Conductive paints contain copper, silver, nickel or graphite. These materials shield a product from electromagnetic interference (EMI), radio frequency interference (RFI) and corrosive environments. Shield painting is also used to prevent electrostatic discharge (ESD).

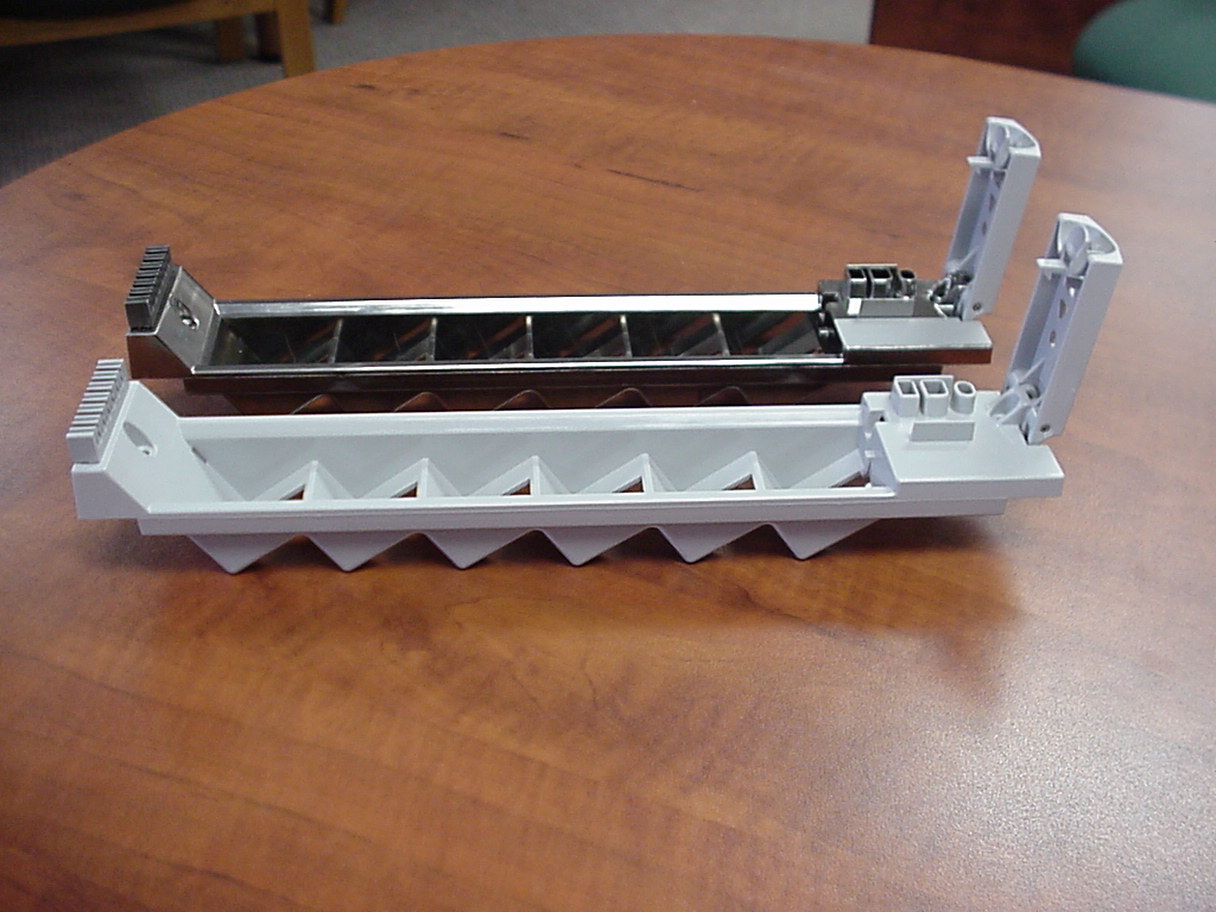

Shield plating protects moulded parts from electromagnetic interference (EMI) and radio frequency interference (RFI), and prevents electrostatic discharge (ESD). The plating process deposits metals such as copper, nickel, tin, gold or chrome on the surface of the plastic part. Parts can have shield plating applied as shown on this before/after image of a faceplate.

We provide this service for customers who wish to customize the aesthetic quality of their moulded products.

(905) 665-6684

jtill@duramould.com

600 Euclid Street Whitby, Ontario L1N 5C2

Join now to stay up to date with our latest news

Copyright © duramould 2023. All rights reserved.